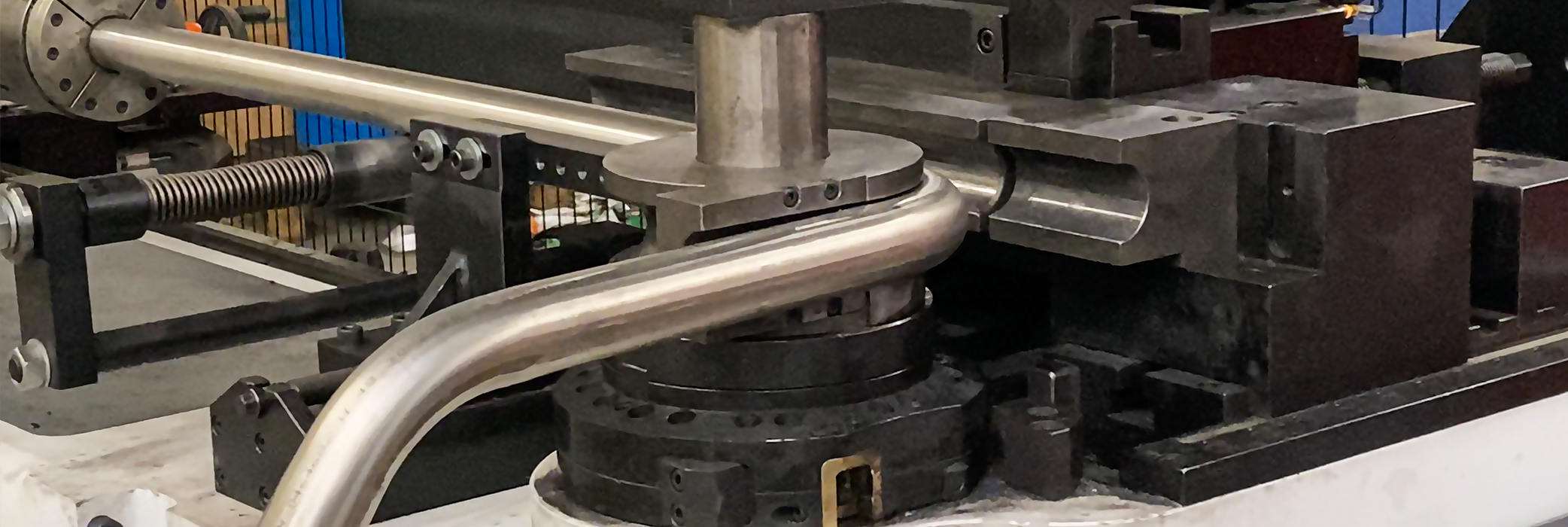

We are offering tube bending service on CNC and NC mandrel tube bending machines. On these machines, the mandrel supports the tube from the inside during bending to achieve minimum deformation and the best bending quality for bends with small radius. Bending is done around the bending axis with a tool with a fixed radius (see the table below for a list of available tools).

Depending on the material used, pipes can be bent with a radius equal to 1.5 times the outer diameter of the pipe with a mandrel bending machine. The thinner the wall thickness and the smaller the bend radius, the more complex tool set is required.

We offer pipe bending services for carbon and stainless steel pipes with a diameter of 12mm-60.3mm and also for square pipes.

Our projects

Available tools

Available tools for AMOB CH80CNC tube bending machine:

| Pipe size | Center Line Radius (CLR): |

| 12x1,5 | 24mm |

| 14x2 | 28mm |

| 15x1,5 | 30mm |

| 16x1,5 | 32mm |

| 17,2x2,4 | 34,4mm |

| 18x1,5 | 36mm |

| 19x1,5 | 38mm |

| 20x1,5 | 40mm |

| 21,3x2,7 | 42,6mm |

| 22x1,5 | 44mm |

| 25x1,5 | 50mm |

| 25x2 | 50mm |

| 26,9x2 | 53,8mm |

| 26,9x2,3 | 53,8mm |

| 26,9x3 | 53,8mm |

| 30x1,5 | 60mm |

| 30x2 | 60mm |

| 32x1,5 | 64mm |

| 32x2 | 64mm |

| 33,7x2 | 67,4mm |

| 33,7x2,3 | 67,4mm |

| 33,7x2,6 | 67,4mm |

| 33,7x3 | 67,4mm |

| 38x1,5 | 76mm |

| 38x2 | 76mm |

| 40x2 | 80mm |

| 40x2,5 | 80mm |

| 42,4x1,5 | 84,8mm |

| 42,4x2 | 84,8mm |

| 42,4x2,6 | 84,8mm |

| 42,4x3 | 84,8mm |

| 42,4x3,2 | 84,8mm |

| 45x2,5 | 90mm |

| 48,3x2 | 96,6mm |

| 48,3x2,6 | 96,6mm |

| 48,3x3 | 96,6mm |

| 50x1,5 | 100mm |

| 60,3x2 | 120,6mm |

| 60,3x3 | 120,6mm |

| Square tubes | |

| 20x20x1,5 | 40mm |

| 20x20x2 | 40mm |

| 25x25x1,5 | 50mm |

| 25x25x2 | 50mm |

| 30x30x1,5 | 60mm |

| 30x30x2 | 60mm |

| 40x20x1,5 | 80mm |

| 40x20x2 | 80mm |

| 40x20x1,5 | 150mm |

| 40x20x2 | 150mm |

| 20x40x1,5 | 120mm |

| 20x40x2 | 120mm |

Available tools for Gelber-Bieger S-50 tube bending machine:

| Pipe size | Center Line Radius (CLR): |

| 12 | 35mm |

| 16x1,5 | 40mm |

| 16x2 | 40mm |

| 20x1,5 | 40mm |

| 20x2 | 40mm |

| 25x1,5 | 50mm |

| 25x2 | 50mm |

| 26,9x2,9 | 55mm |

| 30x2 | 60mm |

| 33,7x2,9 | 70mm |

| 40x2 | 80mm |

| 42,4x2,3 | 85mm |

| 42,4x3,2 | 85mm |

| 48,3x2 | 95mm |

| 48,3x2,9 | 95mm |

| 50x1,5 | 100mm |

| 50x3 | 100mm |

| Square tubes | |

| 25x25x1,5 | 75mm |

| 30x30x1,5 | 90mm |

| 20x40x1,5 | 120mm |

| 20x40x2 | 120mm |

| 40x20x1,5 | 150mm |

| 40x20x2 | 150mm |