Mechanical assembly

Connecting parts by means of pull-through rivets. (picture to be added soon)

Installing rivet-nuts for bolt connections. (picture to be added soon)

Assembly of different products to form a complete unit – mounting handles, casters, etc., mounting wooden parts on outdoor furniture.

Bending small details

Bending iron bars, round steel and square steel.

Maximum bending length 100 mm.

Maximum material sizes:

- iron bar 100 x 15;

- round steel 20 mm;

- square steel 20 x 20.

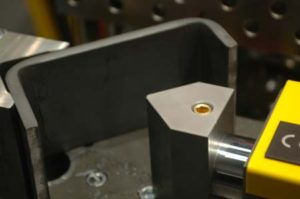

Threading of holes

For threading the holes, we use an electric threader. Maximum hole dimension for carbon and stainless steel is M24 and for aluminum is M32.

Hole punching

Hole punching

Punching different holes in sheet metal. Maximum hole diameter is 36 mm.

Available tools for hole punching:

- round hole punchers: 5, 6, 7, 8, 9, 10, 11, 12, 13, 15, 17, 19, 21, 23, 25, 27, 29, 30, 32, 34, 36

- elongated round hole (oval) punchers: 7x15, 9x20, 10x20, 10x36, 11x22, 11x36, 12x24, 13x36

- square hole punchers: 9x9, 10x10, 11x11, 12x12, 13x13

Profile cutting

We can cut different materials to measure and at various angles. We can process:

- carbon steel

- stainless steel

- aluminium

- plastic

Technical specification of the band saw:

- cutting capacity 90° Ø 260 / 300x260 mm

- cutting capacity 45° right/left Ø 200 / 180 x 180 mm

- cutting capacity 30° right/left Ø 130 / 120 x 120 mm

- we offer profile cutting for our own material, as well as material supplied by the client.

Powder coating and hot-dip galvanising

Products manufactured by us can be ordered with coat finishing – we offer powder coating and hot-dip galvanising. The products can be ordered in many colour shades. Powder coating and hot-dip galvanising is performed by our cooperation partners.